Quality Plastic Injection Molding Begins With Quality Mold!

At Rayleap Plastic, we firmly believe that the cornerstone of quality plastic injection molding lies in the creation of a superior mold. Our commitment to excellence starts at the very beginning, ensuring precision, performance, and perfection in every molding project.

The Mold Manufacturing Process

At Rayleap Plastic, we take pride in our precision and expertise in mold manufacturing. Our dedicated team of professionals follows a meticulously crafted Mold Manufacturing Process to ensure the highest quality molds for a wide range of industries. Here, we provide you with an overview of the key stages involved in our mold manufacturing process:

Moldflow analysis

Moldflow analysis of designing stage will help avoiding the potential risks for runner, which will save time and cost for customers because bad design will ruin a mold.

CNC Process

CNC machining is an integral part of injection molding processes.When you choose Rayleap Plastic as your preferred CNC machining service provider, we harness this knowledge to deliver the requirements of your project to perfection.

Wire EDM Cutting

To achieve intricate details and complex geometries in the mold, we use Electrical Discharge Machining (EDM). This process uses electrical discharges to precisely shape and finish the mold components, ensuring exceptional precision.

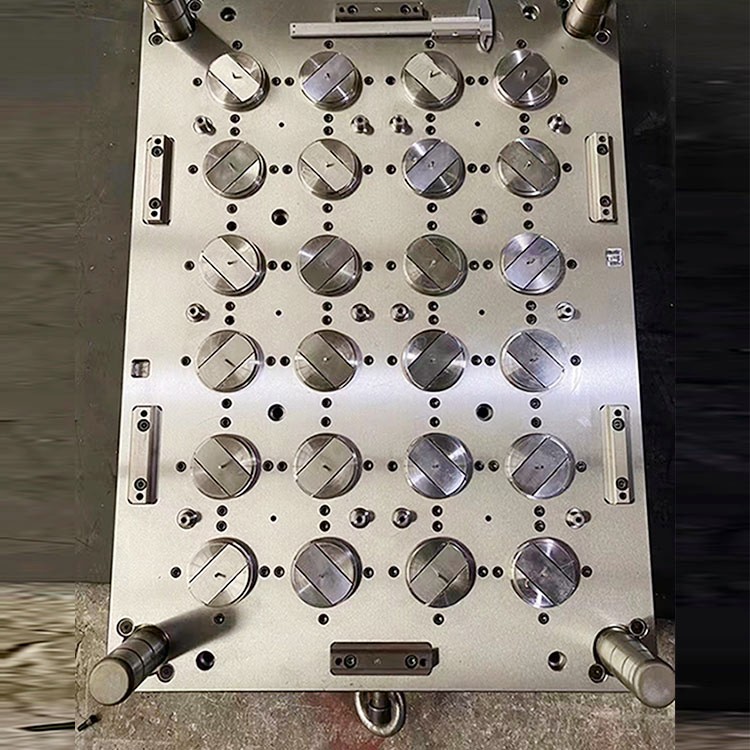

Grinding process

We employ precision grinding to achieve the desired surface finish and tight tolerances on mold components. Grinding ensures that every detail meets the exact specifications for optimal mold functionality.

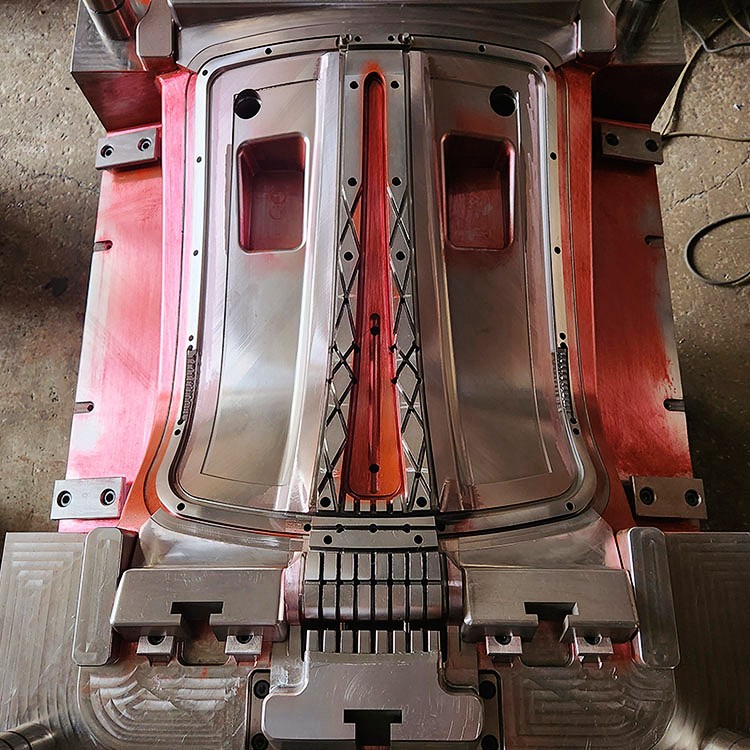

Mold Surface Finish

We pay meticulous attention to the surface finish of the mold. A high-quality surface finish is essential for product release, aesthetics, and functionality. Our finishing processes ensure that your mold meets the highest industry standards.

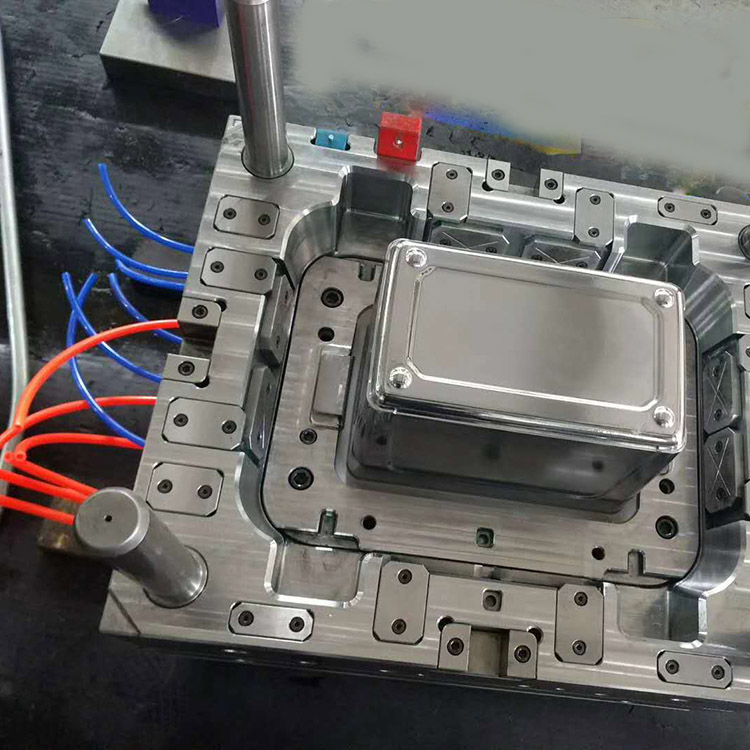

Mold assembly

In this critical stage, we meticulously assemble the various components of the mold, ensuring that every part fits seamlessly. Proper assembly is key to the mold's functionality and longevity.

Plastic Injection Molds Display